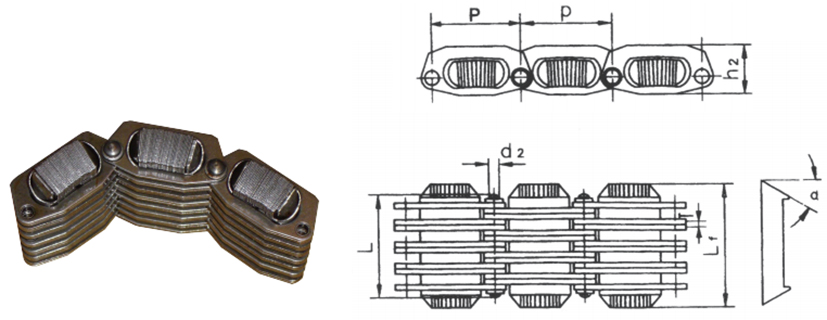

Amaketanga Esivinini Aguquguqukayo, kufaka phakathi Amaketanga Esivinini Aguquguqukayo Ohlobo lwe-PIV/Roller

AMAKEYINI ESIVININI ASISHINTSHA NGOKUNGENAMHLABA

| GL Inombolo ye-Chdn. | I-Pith I-P mm | Ububanzi bephini. d2(ubuningi) mm | Ubude bephinikhodi L(ubuningi) mm | Ukujula kwepuleti h2.(ubuningi) mm | Ubukhulu bepuleti I-T(ubuningi) mm | Ubukhulu bepuleti I-T(ubuningi) mm | Ububanzi phezu kwepuleti lokungqubuzana ngezinga elithile | Amandla okuqina aphezulu Q (min) Kn | Isisindo ngemitha q kg/m |

| AO | 18.75 | 3.00 | 19.50 | 9.50 | 1.0 | 24.00 | 15 | 9.0 | 1.0 |

| Al | 19.00 | 3.00 | 19.50 | 10.60 | 1.5 | 30.44 | 15 | 9.0 | 1.0 |

| A2 | 25.00 | 3.00 | 30.10 | 13.50 | 1.5 | 37.80 | 15 | 21.0 | 2.0 |

| A3 | 28.60 | 3.00 | 35.30 | 16.00 | 1.5 | 44.20 | 15 | 38.5 | 3.0 |

| A4 | 36.00 | 4.00 | 48.50 | 20.50 | 1.5 | 58.50 | 15 | 61.5 | 5.4 |

| A5 | 36.00 | 4.00 | 60.50 | 20.50 | 1.5 | 70.00 | 15 | 71.0 | 6.7 |

| A6 | 44.40 | 5.40 | 70.00 | 23.70 | 1.5 | 77.00 | 15 | 125.0 | 9.0 |

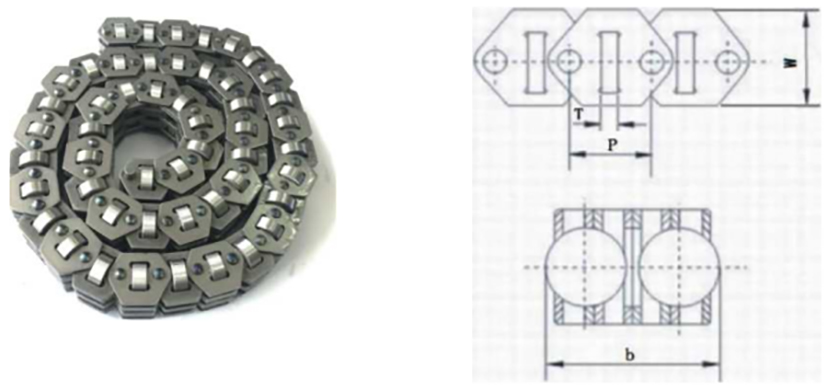

UHLOBO LWE-ROLLER LWEZINETHI ZESIVININI EZIGUQUKA NGOKUNGENAMHLABA

| GL INOMBOLO YEKEYINI | I-PITCH | IPULETI UBUDE | I-ROLLER UBUBANZI | I-ROLLER UKUQINA |

| P | W | b(iminithi) | T (ubuningi) | |

| mm | mm | mm | mm | |

| I-RBO | 10.10 | 923 | 12.00 | 2.90 |

| I-RBI | 1220 | 12.30 | 16.04 | 4.10 |

| I-RB2 | 14.66 | 14.80 | 20.00 | 4.74 |

| I-RB3 | 12.60 | 16.60 | 24.60 | 4.70 |

| RB4 | 14.00 | 20.70 | 31.00 | 5.50 |

| I-RC3 | 1320 | 18.80 | 24.54 | 4.70 |

| I-RC4 | 1620 | 22.50 | 31.00 | 5.30 |

Amaketanga Esivinini Aguquguqukayo Ebhokisi Legiya

1. Amaketanga esivinini aguquguqukayo angenamkhawulo e-PIV:

A0, A1, A2, A3, A4, A5, A6

2. Amaketanga esivinini aguquguqukayo angenamkhawulo ohlobo lwe-roller:

I-PSR1, i-PSR4, i-PSR5, i-RB0, i-RB1, i-RB2, i-RB3, i-RB4, i-RC3, i-RC4 njll.

Umsebenzi: Uma ushintsho lokufaka lugcina isivinini sokujikeleza kokukhipha esizinzile. Imikhiqizo yenziwe ngokukhiqizwa kwensimbi ye-alloy esezingeni eliphezulu. Amapuleti ayabhobozwa futhi acindezelwe ngobuchwepheshe bokucacisa. Iphini, isihlahla, i-roller zishintshwa ngemishini ezenzakalelayo esebenza kahle kakhulu kanye nemishini yokugaya ezenzakalelayo, bese kuba ngokwelashwa ngokushisa kwe-carburization, isithando sebhande le-carbon kanye ne-nitrogen, inqubo yokuqhuma kobuso njll. Ukunemba okuhlanganisiwe ngesimo sembobo yangaphakathi, kujikelezwe yingcindezi ukuqinisekisa ukusebenza kweketanga lonke.